Purpose

The purpose of the Hazard Communication Program is to ensure employees have knowledge about the hazardous chemicals present in the workplace, understand the workplace hazards associated with these chemicals, and recognize how to protect themselves against the hazards. The Occupational Safety and Health Administration’s (OSHA’s) Hazard Communication Standard (29 CFR 1910.1200) was designed to ensure information about hazardous chemicals and protective measures are disseminated to employees. While chemicals may pose a wide range of health hazards (such as irritation, sensitization, and carcinogenicity) and physical hazards (such as flammability, corrosion, and reactivity), the Hazard Communication Program at the University of Alabama (University) was established to ensure employees have appropriate chemical hazard information, including knowledge about the identities and hazards of the chemicals they are exposed to in the workplace. This written program document describes the ways that this information is transmitted to employees to meet the requirements of the Hazard Communication Standard.

1. Program Details

Under the Hazard Communication Program, employees will be informed of the contents of the OSHA Hazard Communications standard, the hazardous properties of chemicals with which employees work, and safe handling procedures and measures employees can take to protect themselves from the hazards associated with these chemicals.

This program applies to all work operations that include University employees when the potential exists for possible exposure to hazardous chemicals under normal working conditions or during emergency situations. All work units of the University will participate in the Hazard Communication Program. In addition, University laboratories will be subject to the University of Alabama Chemical Hygiene Plan and OSHA’s Occupational Exposure to Hazardous Chemicals in Laboratories standard (29 CFR 1910.1450), also known as the Laboratory standard. While some overlap occurs between both the Hazard Communication standard and the Laboratory standard, contact Environmental Health and Safety (EHS) directly to discuss questions or concerns, or to request copies of the Hazard Communication Program.

Program Responsibilities

As the University is viewed as the employer, under the Hazard Communication Program, the following responsibilities have been outlined:

Environmental Health and Safety (EHS)

EHS is responsible for the development and administration of the UA Hazard Communication Program, with responsibility for reviewing and updating the plan and labelling procedures as necessary. The Executive Director of EHS is considered the program coordinator, with overall responsibility for the program. EHS serves as the University authority and subject matter expert for all things related to the Hazard Communication Program. EHS provides onsite generalized hazard communication training, however, upon request the department also reviews and evaluates other University training provided by other University departments pertaining to the Hazard Communication standard. EHS provides assessments, consultation, and evaluation of potential exposure concerns and other services as requested by departments and supervisors.

Department and Unit Supervisors (PIs, Project Director, Manager, etc.)

University department and unit supervisors (PIs, project director, manager, etc.) whose employees could come in contact with, or be exposed to hazardous chemicals, must ensure that documentation is maintained, along with other necessary resources to ensure an appropriate hazard communication plan is implemented. Responsibilities may include, but are not limited to, ensuring proper documentation such as safety data sheets, labels, and training records, providing appropriate engineering controls, and implementing annual reviews of chemical inventories with necessary documentation. Supervisors are responsible for ensuring the Hazard Communication Program is understood by all employees within the department/unit and providing appropriate protective measures including administrative controls and personal protective equipment. It is the responsibility of the department and/or unit supervisor to ensure that routine site-specific training occurs when new chemical hazards are introduced or when new chemical hazards are encountered. Additionally, supervisors are also responsible for ensuring employees are informed of chemical hazards they may encounter due to contractor(s) activities in the area, and to inform contractors of chemical hazards that may be encountered in the University spaces where they are working. Supervisors may delegate some of these tasks to capable and appropriate personnel provided the roles are clear and understood.

Employees

All University employees are responsible for the completion of Hazard Communication Safety Training. Employees must handle and work with hazardous chemicals in a safe manner. Employees are to read the Hazard Communication Program to ensure understanding of the document and responsibilities of each employee. Employees are responsible for informing their supervisor when they encounter any previously unknown hazardous chemical or when there has been an unsafe condition, potential exposure, on-the-job injury, or a near miss related to a hazardous chemical. Employees must practice safe work habits, handle hazardous chemicals according to the guidance provided on the labels and safety data sheets, and properly label secondary containers of hazardous chemicals.

2. Container Labelling

Employees shall verify that all containers received for use are clearly labelled as to the contents, provide the appropriate hazard warnings and pictograms, and list the manufacturer’s name and address. Labels are to be maintained on the containers, including any tanks, totes, or drums used to contain the hazardous chemical. Supervisors will ensure that all containers are appropriately labelled. No container will be released for use until this information is verified.

Employees shall ensure that all secondary containers are labelled with either an extra copy of the original manufacturer’s label or with labels marked with the identity and the appropriate hazard warning and pictograms (see Appendix A). For help with labelling, contact EHS at 205-348-5905.

The University is using a workplace labeling system that relies on the product identifier, signal word, hazard statement(s), precautionary statement(s), pictogram(s) and the contact information of the responsible party or manufacturer (name, address, and telephone number) being provided in English. Pictograms must have either a red or black border. Additionally, the National Fire Protection Association (NFPA) 704 diamond and the relevant numbers for completion of the diamond are necessary to satisfy the recommended in-house workplace label.

3. Safety Data Sheets (SDSs)

Chemical manufacturers and importers are required to evaluate the hazards of the chemicals they produce or import, and to provide information about them through labels on containers and on the SDSs. The manufacturer or importer of a chemical is required by OSHA to develop a SDS that contains detailed information about the chemical’s hazard using a specified format. The distributor or supplier of the chemical is required to provide this SDS to the purchaser. The current format of the SDS contains sixteen sections with specific content. It is the responsibility of the person receiving the hazardous chemical to confirm the receipt of an SDS at the time the shipment is received.

Every department, division, laboratory space, or work unit must establish a procedure for review of each delivery for the presence of possible hazardous chemicals, examination of the corresponding SDS, and inclusion of any new SDS into the standard process to ensure copies of the new SDS are readily accessible to all employees that have the potential for exposure to the chemical. If an SDS is not received at the time of initial shipment, the following procedure should be followed:

Contact the company where the hazardous chemical was purchased, request a copy from the manufacturer, or contact Environmental Health & Safety for specific guidance.

As stated previously, copies of SDSs for all hazardous chemicals to which employees have the potential to exposure, shall be kept in a known and readily accessible location at all times. Supervisors shall maintain these SDSs and communicate to their employees as to the format of storage, access, and location of the SDSs. If SDSs are to be maintained electronically for use, then instructions must be provided, and there must be 24-hour access to the SDSs without use of internet. Otherwise, alternative paper copies must also be provided. SDSs shall be readily available to all employees during each work shift. If an SDS is not available, employees shall contact his/her supervisor for guidance to obtain the SDS and to report the SDS unavailable or missing.

When revised SDSs are received, the following procedures will be followed to replace old SDSs:

Once an updated SDS becomes available for an individual product, replace the existing MSDS or SDS with the new SDS, however it is recommended to retain the older MSDS or SDS as an electronic copy on file especially since existing stocks of the chemicals were purchased under the older MSDS or SDS. Additionally, all MSDSs/SDSs must be maintained on file for 30 years per OSHA’s Access to Employee Exposure and Medical Records Standard. Also remember that the content of MSDSs and SDSs for pesticides differ, so a copy of both documents must be maintained to ensure compliance from both OSHA Hazard Communication 2012 and Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), which regulates pesticides products.

Procedures are also in place for EHS to assist in obtaining SDSs and to review incoming SDSs for new or significant health and safety information when requested by departments, laboratory spaces, or work units due to concerns regarding the hazardous chemical.

4. Employee Training and Information

EHS is responsible for the University Hazard Communication Program and will ensure that all program elements, including training requirements, are carried out.

All University employees who work with or can become potentially exposed to hazardous chemicals will receive initial training on the hazard communication standard as part of this plan. Each new employee will complete online or in-person general Hazard Communication Training. Additionally, employees will receive a second phase of job-specific safety training which is documented by the employee’s supervisor. Supervisors are to provide on-site safety training related to the hazardous chemicals present in the worksite and are to provide the employee information on the location of the SDS file, list of hazardous chemicals, and the written Hazard Communication program. For more information on safety training, review the UA Safety Training Policy.

Hazard Communication training is provided to all University employees. It covers the following information:

- An overview of the OSHA hazard communication standard

- An overview of hazardous chemicals or operations where hazardous chemicals could be present or used in a work area

- The physical and health risks of hazardous chemicals

- Methods and observations that may be used to detect the presence or release of a hazardous chemical in the work area

- Steps that are taken to reduce or prevent exposure to hazardous chemicals

- An overview of labels and SDSs received on shipped chemicals and the workplace labelling system to ensure employees have an understanding of hazard information including pictograms, signal words, hazard statements and precautionary statements

- Emergency procedures to follow if employees have concerns or may have experienced a possible exposure to a hazardous chemical

- The location and availability of the written Hazard Communication Program, the list of hazardous chemicals, and safety data sheets related to the hazardous chemicals

Prior to introducing a new chemical hazard into any area, each employee in that section shall be provided information and training by their supervisor as outlined below for the new chemical hazard. The training format will be as follows:

Review of the SDS, review of the specified use of the hazardous chemical (including dilution if required), review of the physical and/or health risks of the hazardous chemical, review of the controls in place to reduce or prevent exposure or release of the chemical, use of PPE and review of emergency procedures if any employee is exposed to the hazardous chemical.

5. Hazardous Non-routine Tasks

Periodically, employees are required to perform non-routine tasks that include hazardous chemicals. Prior to starting work on such projects, each affected employee will be given information by their supervisor about the hazardous chemicals the employee may encounter during such activity. This information will include specific chemical hazards, protective and safety measures the employee should use, and steps the University is taking to reduce the hazards, and emergency procedures.

6. Informing Other Employers/Contractors

It is the responsibility of the University to provide other employers and contractors with information about hazardous chemicals that their employees may be exposed to on a University job site and suggest or require certain precautions for employees. Similarly, it is the responsibility of the Project Manager or Contract Supervisor to obtain information about hazardous chemicals used by other employers (contractors) and provide this information to those working in or near the space.

Other employers and contractors will be provided with SDSs for hazardous chemicals generated, that exist, or are used in the area where the contractor or employer will be providing assistance. This information will be distributed by email or by paper copy. In addition to providing a copy of an SDS to other employers and/or contractors, these employers and contractors will also be informed of necessary precautionary measures to protect employees that may be exposed to the hazardous chemicals.

Also, other employers or contractors will be informed of the hazard labels used by the University. Similarly, the Project Manager or Contract Supervisor must also obtain information about the hazard labels used by other employers (contractors) doing work on campus and provide this label information to EHS (specifically if a symbolic or numerical labelling system is used that will require additional information to understand the labels used for the hazardous chemicals to which employees may have an exposure).

7. List of Hazardous Chemicals

Each department or unit maintains a list of all known hazardous chemicals used by employees. Included with the list of hazardous chemicals are the SDSs for each chemical. This list must include the name of the chemical, the manufacturer, the quantity, and the work area or means in which the chemical is used by the department or unit. Further information on each chemical may be obtained from the SDSs. The location of the list and the SDSs may vary by department or unit. The location of this information must be shared with each employee at time of hire by their supervisor.

When new chemicals are received, the list of hazardous chemicals shall be updated (including date the chemicals were introduced) as soon as possible, or at least within 30 days. To ensure any new chemical is added in a timely manner, the following procedures shall be followed:

As soon as the new chemical is received, prior to introducing a new chemical hazard into any area, each employee in that section shall be provided information and training by their supervisor. (Additional information regarding this training is located in “Employee Training and Information”).

8. Chemicals in Unlabeled Pipes

Work activities are sometimes performed by employees in areas where chemicals are transferred through unlabeled pipes. Prior to starting work in these areas, the employee shall verify the:

- Chemical in the pipes

- Potential hazards

- Required safety precautions

9. Program Availability

A copy of this Hazard Communication Program will be made available, upon request, to employees and their representatives. A master chemical inventory system is maintained at EHS which includes hazardous chemicals maintained and used within laboratory spaces. SDSs are available for chemicals contained in the inventory by contacting EHS. Additional useful information, such as the location of the chemical, scientific name, CAS number, etc., can also be found in the inventory system. For specific concerns related to a potential hazardous chemical or SDS, contact EHS at 205-348-5905.

Appendix A

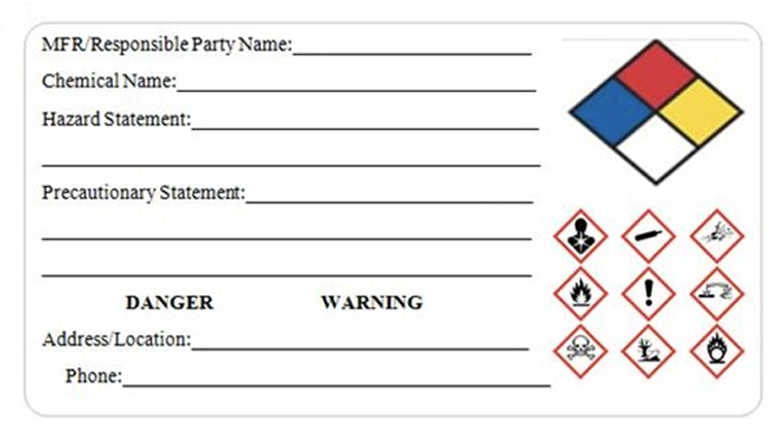

Below is an example of a label that can be used for a secondary container or when the manufacturer’s label has been either removed or defaced. The example label requires the completion of the NFPA 704 diamond, circling the word “Danger” or “Warning” as the required signal word, circling the relating pictograms and marking out the unrelated pictograms, and completion of the remaining sections including manufacturer or responsible party name, chemical name, hazard statements, precautionary statements, manufacturer’s or responsible party’s address/location and contact numbers associated with the manufacturer or responsible party. Other labels are permissible as long as they provide the required information. For access to a template for this label, or additional information related to the pictograms, signal words, hazard statements, precautionary statements or the NFPA diamond, contact EHS at 205-348-5905 or visit the EHS website.

The Safety Data Sheets (SDS) for the hazardous chemical contains the required information for the label in the various sections. For instance, Section 1 identifies the chemical and provides the contact information for the chemical manufacturer, while Section 2 contains the signal word, hazard statements, pictograms, precautionary statements and hazard classification of the chemical.

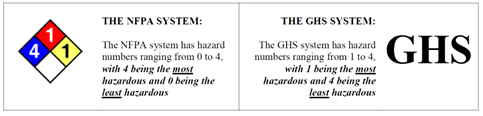

Remember the NFPA system and the GHS system are not the same. In fact, the number system is just the opposite.

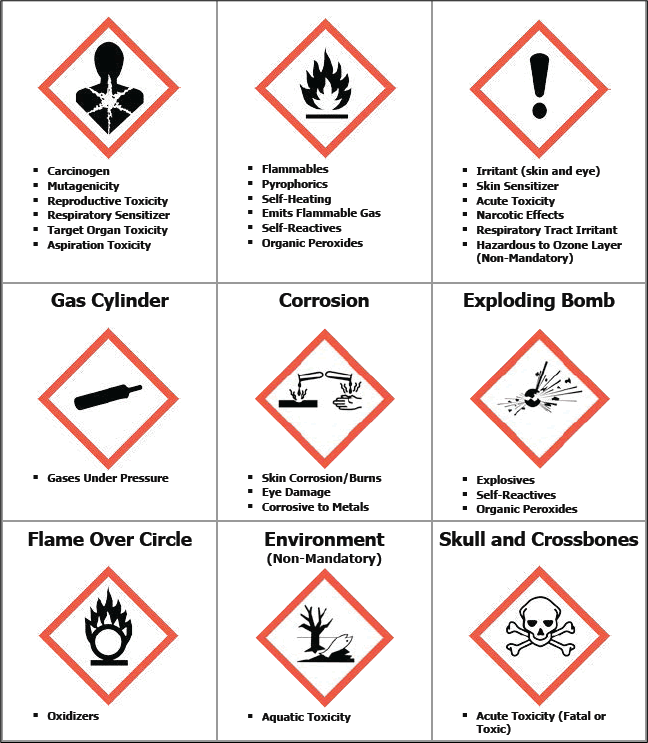

For clarification see the NFPA OSHA Quick Card Comparison of NFPA 704 and HazCom 2012 Labels. A brief summary of pictograms follows to help you when completing the new label format.

HCS Pictograms and Hazards